The company

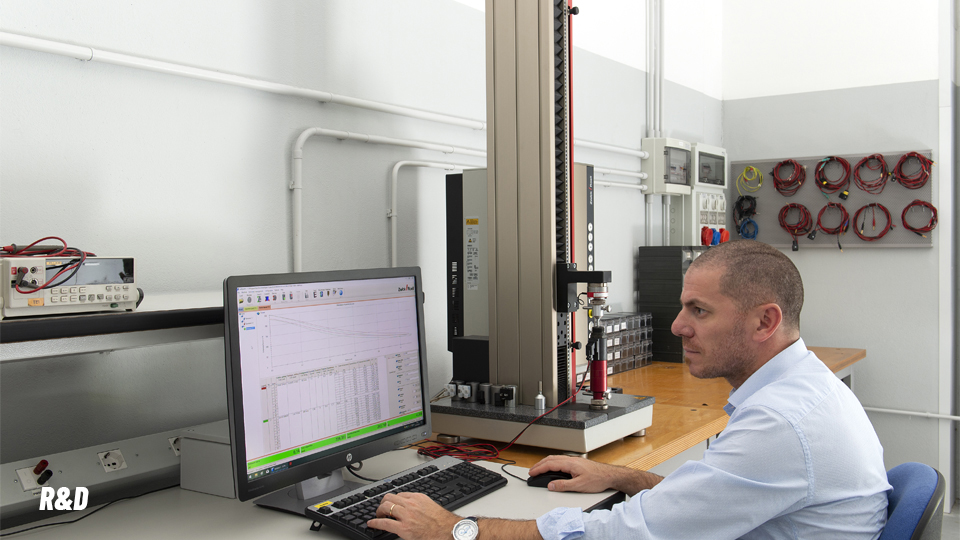

Italmagneti is a company customer needs oriented. The investments in research and develop, in new technologies, human resource and logistic allow us to offer to the market the last innovative solutions.

Italmagneti skills:

- Exclusive know how to design the products.

- Deep knowledge to realize the products, trough mechanical working phases and welding process.

- Wide and strong experience in the hydraulic technologies.

- Product reliability.

- Fast and precise after sale service.

Thanks to these characteristics Italmagneti is quick in the answers, flexible to find the right solution and competitive even for small productions.